Medical-grade silicone has a wide application in the healthcare sector due to its extensive usage. LSR Injection Molding can combine silicone components. Hence, it is a key consideration for medical-grade silicone parts.

Scalable silicone components are extensively used in healthcare because they are flexible and long-lasting. These are used in different medical applications. Silicone parts are highly preferred nowadays because of the high prevalence of cosmetic surgeries.

LSR Injection Molding is highly applicable in the healthcare setting due to its high precision and capability to resist extreme temperatures. This is significant in producing several medical-grade parts. This blog examines why this process is effective in varied medical applications.

What is LSR Injection Molding?

This is a thermoset process that is responsible for preparing different silicone parts. These rubber parts are highly durable and precise. LSR possesses a good fluidity level, which is injected into silicone molds to create high-precision components.

In this process, two silicone compounds are mixed and injected into a heated mold cavity. This accounts for solidification and quick chemical cross-linking to produce high-volume parts.

LSR Injection Molding is better than rubber molding or compression because it produces complicated and highly precise components. This ensures an excellent material quality. Let’s compare this process with other silicon molding processes.

| Features | LSR Injection Molding | Compression Molding | Transfer Molding |

| Precision | High | Medium | Medium |

| Speed of production | Fast | Slow | Moderate |

| Automation | High | Low | Medium |

| Best for | Tight tolerance, high volume, and tight tolerance | Simple shapes, low volumes, and large parts | Prercise dimensions and products with inserts |

Table: Comparing different types of molding

Need for Medical-Grade Silicon

Medical-grade silicon is considered in certain medical devices, like catheters, medical implants, prosthetics, respiratory masks, etc. But why is it preferred? Here are the top characteristics.

- Safety: Medical-grade silicon is safe for humans. Silicone parts do not account for any allergic reaction or irritation, thereby making it effective for medical devices. This made an item easily applicable to a patient’s body, inside or outside. Its biocompatibility is responsible for preventing the release of any hazardous substance.

- Durability: Medical-grade silicon is highly durable. Hence, considering it for medical devices makes the products last longer. There is also no chance of wearing.

- Chemical and temperature resistance: Medical-grade silicone does not degrade in high temperatures or when exposed to any chemical. This does not react with your body fluid or any medicine.

Why LSR Injection Molding is Beneficial for Medical Applications?

LSR Injection Molding is advantageous for medical applications for various reasons. These are.

Ultra-High Precision

LSR Injection Molding has a high level of precision due to its low-viscosity liquid state. This accounts for a tight tolerance level, thereby resulting in the creation of accurate and uniform parts. This makes it a key consideration in medical devices. The tolerance level ranges from ±0.05 mm to ±0.01 mm.

Sterile-Ready

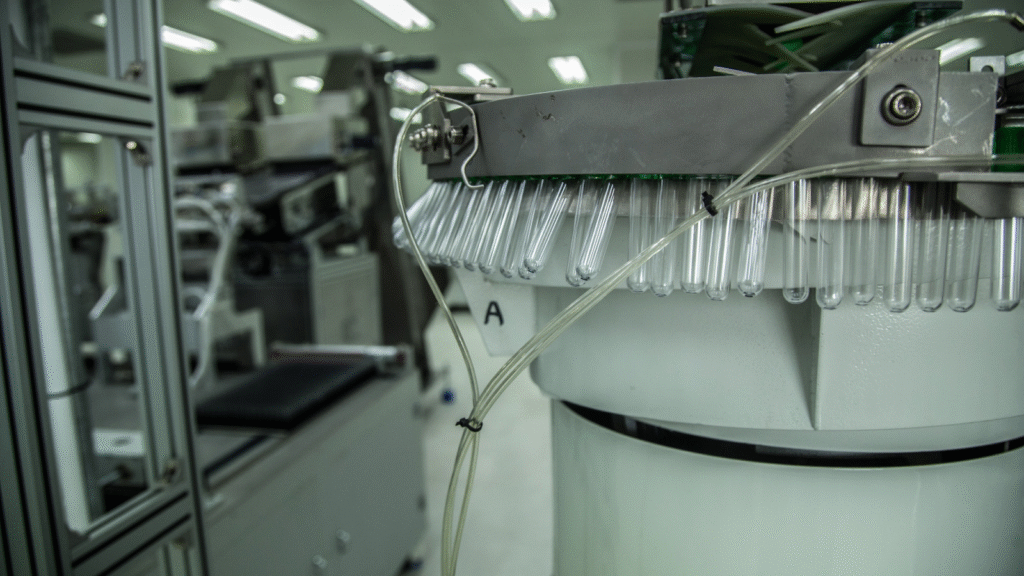

LSR has a high level of resistance to bacterial growth. This made it deal with various sterilisation processes like gamma radiation, autoclaving, etc. This is effective for sterile medical components because it is processed in clean rooms.

High Repeatability

LSR Injection Molding has an automated control of the overall procedure. This accounts for 24/7 production. This automation reduces human error while ensuring top-quality materials. This helps the manufacturers to produce top-quality medical products.

Cleanroom Compatibility

Based on cleanroom compatibility in LSR Injection Molding, patient safety is ensured because contaminants like bacteria, microbes, dust, etc. are prevented. Hence, top-quality medical devices are produced, and no compromise is made with their performance. Different FDA regulations can be met because of the controlled environment.

How Are Medical-grade LSR Components Applied in Real Scenarios?

LSR Injection Molding is highly suitable for medical-grade silicone parts due to the extensive real-world applications. Let’s check out the key aspects.

Respiratory Items

LSR maintains its physical properties under extreme conditions, thereby offering leaf-proof connections. This makes it applicable for different respiratory components, like valves, masks, and seals.

Implantable Devices

Due to its excellent biocompatibility, it is considered in artificial joints, heart valves, etc. Such implantable devices benefit from LSR’s capability to resist tissues and fluids in the body, thereby acknowledging patient safety.

Wearable Medical Devices

LSR is a skin-friendly material, which makes it a key consideration in smart watches, biosensors, continuous glucose monitors, etc. People do not feel uncomfortable while wearing such devices.

How LSR Injection Molding Solves Various Issues in the Medical Field?

Medical devices should possess high sterility and safety when they come in contact with the human body. LSR solves this issue by dealing with different sterilisation processes. Such materials follow strict regulations like ISO 10993 and USP Class VI.

The issue of needing intricate components with a good tolerance level in medical devices is solved by LSR. Due to its shear-thinning properties, it can flow into the thinnest mold cavity.

Medical devices must work under different temperatures. This material is perfect in this case because of its temperature-resistance and chemical durability properties.

To Conclude

LSR Injection Molding, with its high efficiency, is used in different medical devices. Medical-grade silicon is preferred in devices, like catheters, tubes, and wearable devices. Prioritising this process ensures patient safety so that quality treatment can be provided.

Producing Medical-grade Silicon Components

LSR Injection Molding has a high level of applicability in silicon components. Being sterile-ready, it is useful in producing medical devices. Find an experienced manufacturer who specialises in molding.