Industrial Switches In Smart Factories: Real-Time Automation Enabler

Smart factories are revolutionizing industry, and the unsung heroes of interconnectivity, industrial switches, are leading this charge. These rugged devices enable real-time data transmission by connecting effortlessly with machines, sensors, and control systems. Industrial Switches In Smart Factories: Real-Time Automation Enabler.

Increased efficiency and responsiveness in operations are natural consequences.

In this new setup, discovering how industrial switches allow for automation can make your factory an intelligent, forward-thinking place.

What’s an Industrial Switch

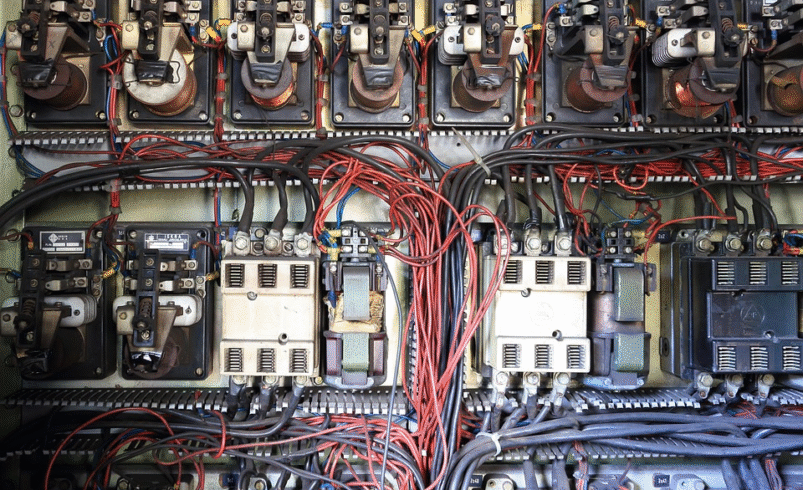

An industrial switch is a tough Ethernet switch capable of withstanding extreme temperatures, vibrations, and factory floor dust. It also offers capabilities like Power over Ethernet (PoE), network redundancy, and industrial protocol support.

So, choosing the right switch ensures safe, reliable, and low-latency communication between programmable logic controllers (PLCs), sensors, robots, and human-machine interfaces (HMIs).

Fundamental Role of Industrial Switches in Smart Manufacturing

First, industrial switches form the core of smart factory networks, facilitating real-time communications and tight control loops required by precision manufacturing. Uniform data flow is imperative with increasing growth in automation systems, particularly for latency-sensitive applications like motor synchronization or emergency stop systems.

Second, they offer segmentation and prioritization functionalities that separate critical control traffic from common data, ensuring that necessary latency-sensitive signals are well- prioritized. Moving on, let’s discuss their significance in real-time setups.

1. Building Resilient Network Infrastructure

Smart factory setups are never tidy. Dust, heat, or vibration might short out less robust equipment. Industrial switches, however, are hardened with rugged enclosures and constructions that withstand such abusive conditions. Although managed versions provide redundancy support in Rapid Spanning Tree or ring topologies, another immediately picks up communication if one path is lost. To ensure production doesn’t halt and uptime remains excellent.

2. Supporting Real-Time Data Exchange

Real-time communications are not an option; they’re the only solution in applications where real-time timing is critical. For instance, synchronized robots or CNC tools are based on data with unnoticeable latency. Generic office-quality switches, however, cause jitter or delay. By nature, industrial switches support deterministic operation and tend to have protocols that ensure delivery within tight time windows.

3. Protocol Support and Interoperability

Industrial environments use protocols such as PROFINET, Ethernet/IP, Modbus TCP, and Time Sensitive Networking (TSN). They natively support industrial switches and, therefore, have unproblematic inter-device connectivity between vendors. So with more and more use of heterogeneous technology by factories, the switch is hardly struggling to integrate without establishing complex workarounds.

4. Security and Network Segmentation

Along with making factory floors smarter, cyberattacks have also become smarter. Industrial switches work the opposite way by isolating networks, restricting sensitive devices from office general networks, and enforcing access control lists (ACLs). Managed switches have encryption and intrusion detection, up to industrial cybersecurity standards like IEC 62443. They make a very effective barrier against unauthorized access and tampering.

5. Scalability and Redundancy

Manufacturing has to evolve rapidly, especially in intelligent modular factories. Networks should, therefore, scale very easily. Industrial switches offer stacking capabilities via SFP ports or rings, allowing for easy incorporation of new machines into topologies. Furthermore, redundancy provides no single point of failure, and performance is still excellent even with maintenance or unexpected events. Consequently, your network is still strong and flexible.

6. Powering Devices and Simplifying Cabling

Some industrial switches offer Power over Ethernet (PoE+ or PoE++) to ensure easy installation with power and data through a single cable. It comes in handy for IP-based sensors, access points, cameras, and other devices. The installations become neater, quicker, and less prone to error.

7. Applications in Smart Factories and Beyond

Wherever they are used in assembly lines, conveyor belts, or automated test stations, industrial switches enable fast data transfer, real-time control, and remote monitoring. Their use is also advantageous in innovative grid installations, transportation hubs, surveillance networks, and city infrastructures, each requiring reliable, intelligent communications.

8. Smart Traffic Management

Controlled industrial switches in large factories or smart campuses to optimize network traffic throughput. They give precedence to control commands required for operation and spread less-priority data to avoid congestion. Thus, mission-critical systems are provided with the bandwidth and responsiveness they need, even as data volumes increase.

9. Realizing Real‑Time Automation With IIoT

As the Industrial Internet of Things (IIoT) grows, factories can collect and process vast volumes of sensor data. However, reliable real-time insights delivery is impossible without a low-latency, deterministic network. Industrial switches are therefore needed to link edge devices, gateways, and cloud infrastructure, so predictive maintenance, digital twins, and remote diagnostics become practical and responsive.

Choosing the Correct Industrial Switch

When selecting a switch, determine whether you need managed control or a simple plug-and-play installation. Also, environmental needs such as operating temperature and shock resistance must be specified. If you are deploying powered devices or IP sensors, you may need support for PoE. Finally, ensure that you have redundancy, protocol interoperability, and security options to future-proof your deployment.

Practical Insights for Smooth Deployment

Installing industrial switches requires site planning and consulting with IT and OT teams. If managed switches are introduced, you must configure VLANs, ACLs, and quality-of-service settings. Hence, it’s wise to engage network specialists. Additionally, ongoing monitoring ensures switches are performing correctly and helps detect anomalies early.

Conclusion

Industrial switch investment is more than hardware addition—It’s getting your entire factory into thinking, acting, and responding dynamically. These rugged devices give the foundation of your automation capabilities with real-time performance, reliability, and interoperability. As technology evolves, industrial switches are the network’s rock-solid foundation that connects machines in today’s factories and enables innovations tomorrow.

So, when you’re looking to make your facility a genuinely smart operation, start with a solid, secure switching platform that fits your needs. And then build on it with confidence, next-generation automation and IIoT solutions.

A foundation that, in the long run, will hold together not only better efficiency and uptime but also a pipeline of future potential—everything from predictive maintenance to sustainable, adaptive manufacturing ecosystems.