Preventing Equipment Failures with Advanced Vibration Analysis

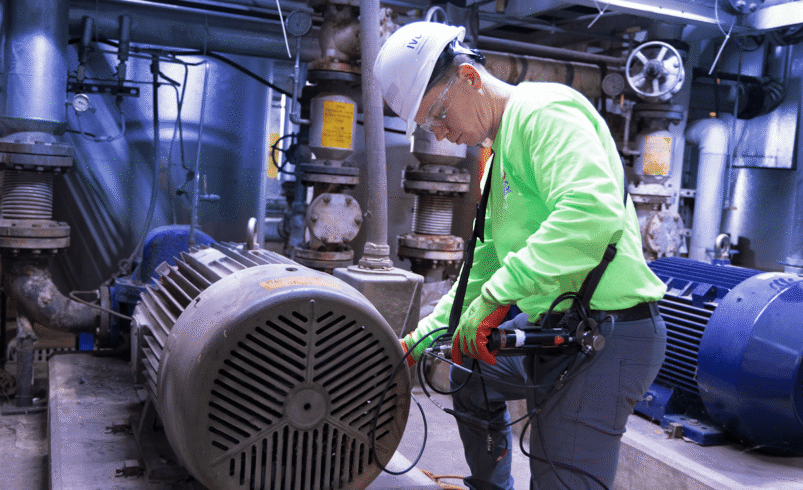

In industrial operations, equipment failure is a costly and frequently hazardous reality. Unplanned downtime can result in production losses, compromised safety, and costly repairs for any type of facility, including industrial plants, energy facilities, and transportation hubs. Conventional maintenance techniques, such as scheduled or reactive maintenance, frequently fail to detect problems before they become more serious. In this regard, sophisticated vibration analysis has become a potent instrument for anticipating, identifying, and averting mechanical breakdowns before they happen. Organizations can obtain important insights into machine health and take proactive measures to address abnormalities by closely monitoring equipment vibrations.

Comprehending the Science Underpinning Vibration Analysis

Fundamentally, vibration analysis is the measurement of mechanical component oscillations while they are in operation. Under normal functioning conditions, each piece of equipment has a distinct vibration signature. This signature varies subtly but noticeably as parts like shafts, gears, or bearings start to wear out or malfunction. To analyze these differences, advanced vibration analysis uses diagnostic software, signal processing algorithms, and high-resolution sensors. Specific issues like imbalance, misalignment, bearing flaws, or looseness might be detected by it. Long before a catastrophic failure happens, professionals can use these insights to identify problems with surprising precision and put corrective measures in place.

Predictive Maintenance Program Integration

A key component of predictive maintenance plans is advanced vibration analysis. Instead of following a set timetable, predictive maintenance focuses on evaluating the actual state of machinery to ascertain when service is required. When regularly gathered and examined, vibration data provides a wealth of up-to-date information about the state of the equipment. Organizations may now automate the interpretation of vibration patterns and get warnings when anomalies are found, thanks to cloud-based systems and machine learning algorithms. Maintenance teams may optimize labor and resource allocation by prioritizing interventions based on data-driven insights, thanks to this connection.

Cost-Cutting and Efficiency in Operations

The possibility of modern vibration analysis to lower maintenance costs is among its most attractive benefits. Unexpected malfunctions frequently result in expensive downtime, quick part deliveries, and emergency repairs. On the other hand, by enabling planned and timely maintenance, vibration monitoring-based predictive diagnostics can significantly reduce these costs. Additionally, sophisticated analysis techniques prolong component life and cut waste by preventing needless maintenance on equipment that is still in good shape. Energy savings are another benefit of this efficiency; well-performing machines use less energy and endure less mechanical strain. For businesses that use trustworthy machine vibration analysis, the long-term effects on cost reduction and operational effectiveness can be substantial, providing an alluring return on investment.

Improving Dependability and Safety

In addition to causing financial harm, mechanical failures can present significant safety risks. In sectors involving pressurized systems, high-speed machinery, or volatile chemicals, a single piece of equipment failure might result in mishaps with serious repercussions. Businesses can identify possible failure indicators long before they become safety concerns by using sophisticated vibration analysis. This helps businesses adhere to occupational health and safety laws while also protecting employees. Additionally, when equipment operates more reliably and predictably, industrial processes become more reliable. Improved safety and dependability also help businesses establish a better reputation and more trust with customers and authorities, establishing them as pioneers in proactive asset management.

Technological Developments and Future Trends

Thanks to advancements in artificial intelligence, wireless connectivity, and sensor technologies, the field of vibration analysis is evolving rapidly. Even in challenging or unreachable locations, modern systems can now continuously and remotely monitor equipment in real-time. By combining data from whole facilities, integration with the Industrial Internet of Things (IIoT) provides a comprehensive picture of operational health. AI-powered diagnostic systems can enhance defect detection and provide optimal maintenance regimens by learning from prior vibration data. Vibration analysis should become a normal part of Industry 4.0 ecosystems and smart manufacturing as these technologies become more accessible and user-friendly. Businesses that make early investments in these breakthroughs stand to gain a competitive advantage in terms of cost-effectiveness, productivity, and dependability.

Industry approaches to equipment reliability and maintenance are changing as a result of advanced vibration analysis. Adopting modern vibration analysis is not only a wise decision for companies looking to maintain their competitiveness in a world that is becoming more automated and efficiency-driven, but it is also necessary for long-term success.